Confidence in Quality

At MSP Industries, we pride ourselves for producing the highest quality, precision machine components to exacting standards. Our departments work together to ensure that your components are processed, developed and delivered to the highest quality standards.

Our quality assurance highlights:

- ISO 9001:2015 Certified by NQA

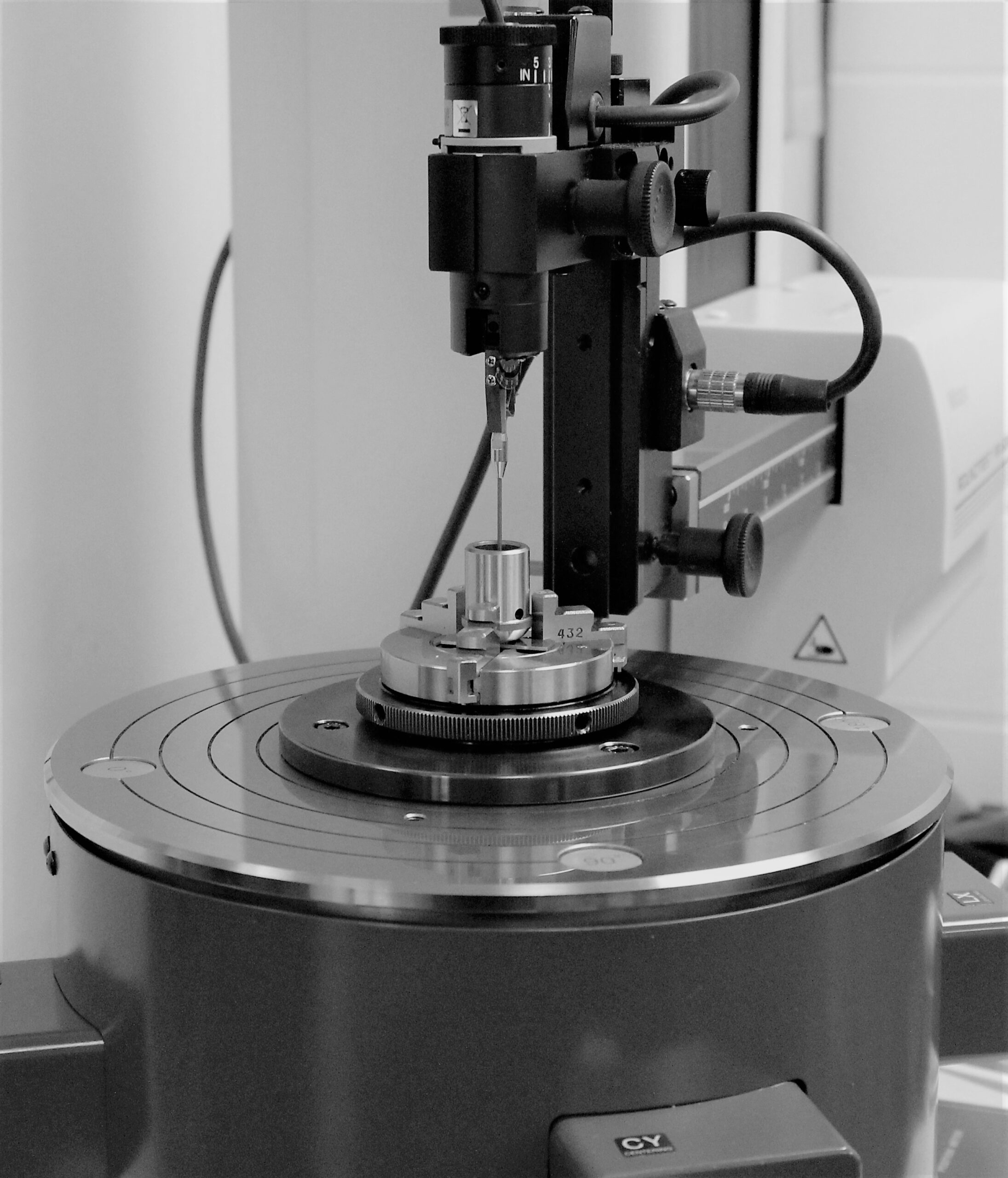

- Coordinate Measuring Machines (CMM)

- In-house quality team that oversees all phases of production

- In-house calibration team to maintain all measurement tools

Customer satisfaction is our priority here at MSP. Our Quality Systems Manual is integrated throughout the company, from the plant floor to upper management, to manufacture and deliver only the best parts that our customers deserve.

Contact us to find out how we can be your solution.