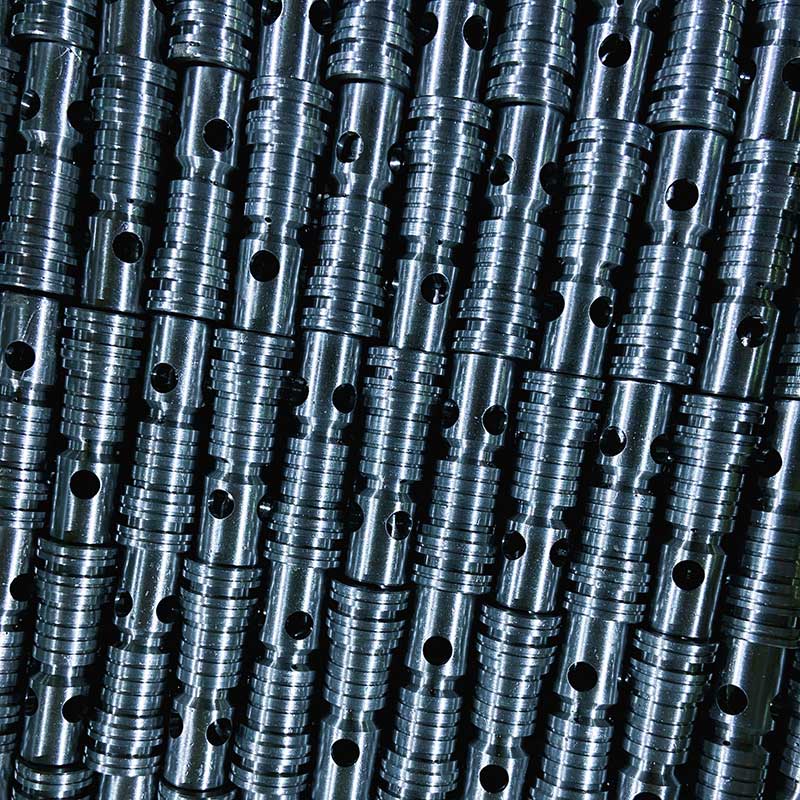

Adapter

Hydraulic Machined Component Requirements and Considerations

Hydraulic systems operate under high pressure and require components that meet exacting standards to ensure functionality and safety. Key considerations for hydraulic equipment components include:

- Precision and Tolerances – Hydraulic components must be machined with tight tolerances to ensure leak-proof operation, efficient fluid flow, and proper sealing within the system.

- Material Strength and Durability – Components must be made from high-strength materials such as stainless steel, aluminum, and alloy steels to withstand high-pressure conditions, corrosion, and wear.

- Surface Finish Requirements – Proper surface finishes are essential to minimize friction, prevent fluid leakage, and ensure optimal performance of seals and moving parts.

- Pressure and Load Resistance – Hydraulic components must be designed to endure extreme pressure and load variations without failure.

- Customization Needs – Many hydraulic applications require custom components to fit unique system designs and performance requirements.

- Regulatory Compliance – Components must adhere to industry standards to ensure operational safety and reliability.

- Consistency and Repeatability – Manufacturers require consistency across production batches to ensure uniform system performance and ease of maintenance.

MSP Industries is Equipped to Meet Hydraulic Machined Component Needs

MSP Industries leverages advanced machining capabilities and years of industry experience to produce high-precision hydraulic components, including:

- Valve Bodies and Manifolds

- Pump and Motor Components

- Cylinder Components

- Fittings and Connectors

- Hydraulic Flanges and Blocks

MSP Industries uses the latest CNC machining, multi-axis milling, turning, and grinding technologies to achieve the precision and quality required for hydraulic applications.

MSP Industries Offers Advantages to Hydraulic Component Manufacturers

Partnering with MSP Industries provides hydraulic equipment manufacturers with several strategic advantages, including:

- Advanced Machining Capabilities – Utilizing cutting-edge CNC and multi-axis machining technologies to achieve superior precision and repeatability.

- Material Expertise – Experience working with high-strength materials and coatings that enhance the longevity and performance of hydraulic components.

- Custom Engineering Solutions – MSP collaborates closely with customers to develop tailored solutions that meet specific hydraulic system requirements.

- Stringent Quality Control – Comprehensive inspection processes, including CMM (Coordinate Measuring Machine) and pressure testing, ensure that every component meets performance expectations.

- Scalable Production – Whether producing prototypes or large-scale production runs, MSP offers flexible manufacturing solutions to meet customer demand.

- On-Time Delivery – Robust supply chain management ensures timely delivery to support manufacturers’ production schedules and minimize downtime.

MSP Industries is a trusted partner for hydraulic component manufacturers, offering precision-machined components that enhance system efficiency, reliability, and durability across a range of applications. Contact us to discuss your needs.